DuoPEX Water

Properties

The DuoPEX Water Pipe and Fitting System is a revolutionary alternative for the professional plumber, makes any job quicker and easier.

DuoPEX Water Pipe

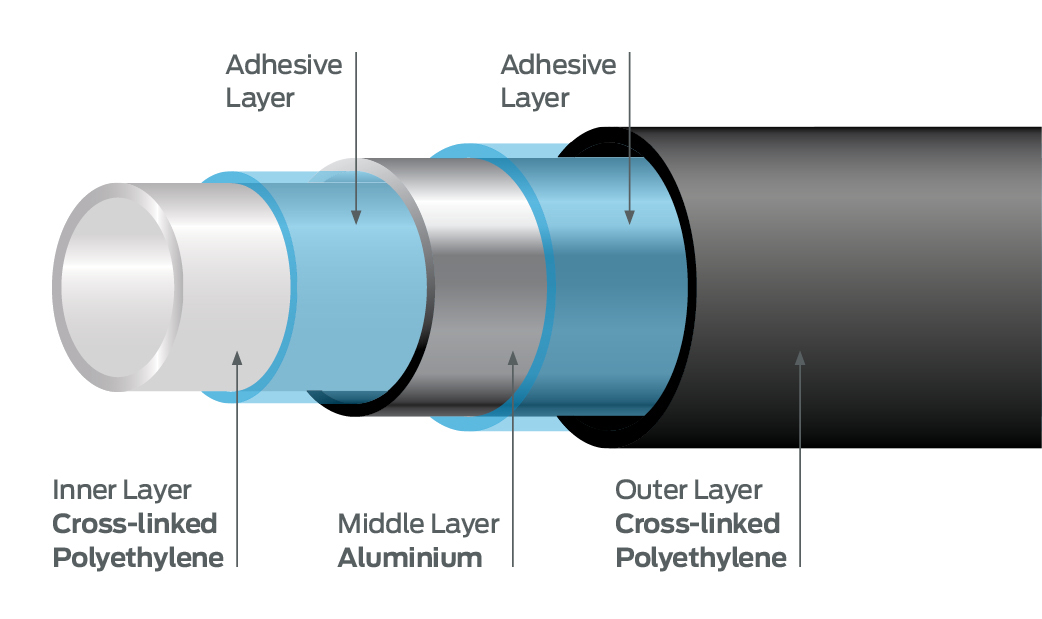

DuoPEX Water pipe is a multi-layer or composite system, designed to be used in potable hot and cold water systems and can also be used for heating purposes.

DuoPEX Water pipe consists of:

- An inner layer of cross-linked polyethylene (PEX)

- An aluminium layer

- An outer layer of cross-linked polyethylene (PEX)

- Inner and outer adhesive layers

Do not use pipes that have kinks, cuts, deep scratches, squashed ends, imperfections or have been in contact with contaminating substances. Such pipe should be cut out and replaced, as these conditions may affect the integrity of the system.

DuoPEX Water pipe in sizes 32mm to 63mm has a black outer layer, which is in keeping with the Auspex hot and cold water pipe.

16mm to 26mm pipe is also available, the outer layer is PE and is coloured white. It also carries a Watermark License and can be supplied in pre-insulated coils.

DuoPEX Water Fittings

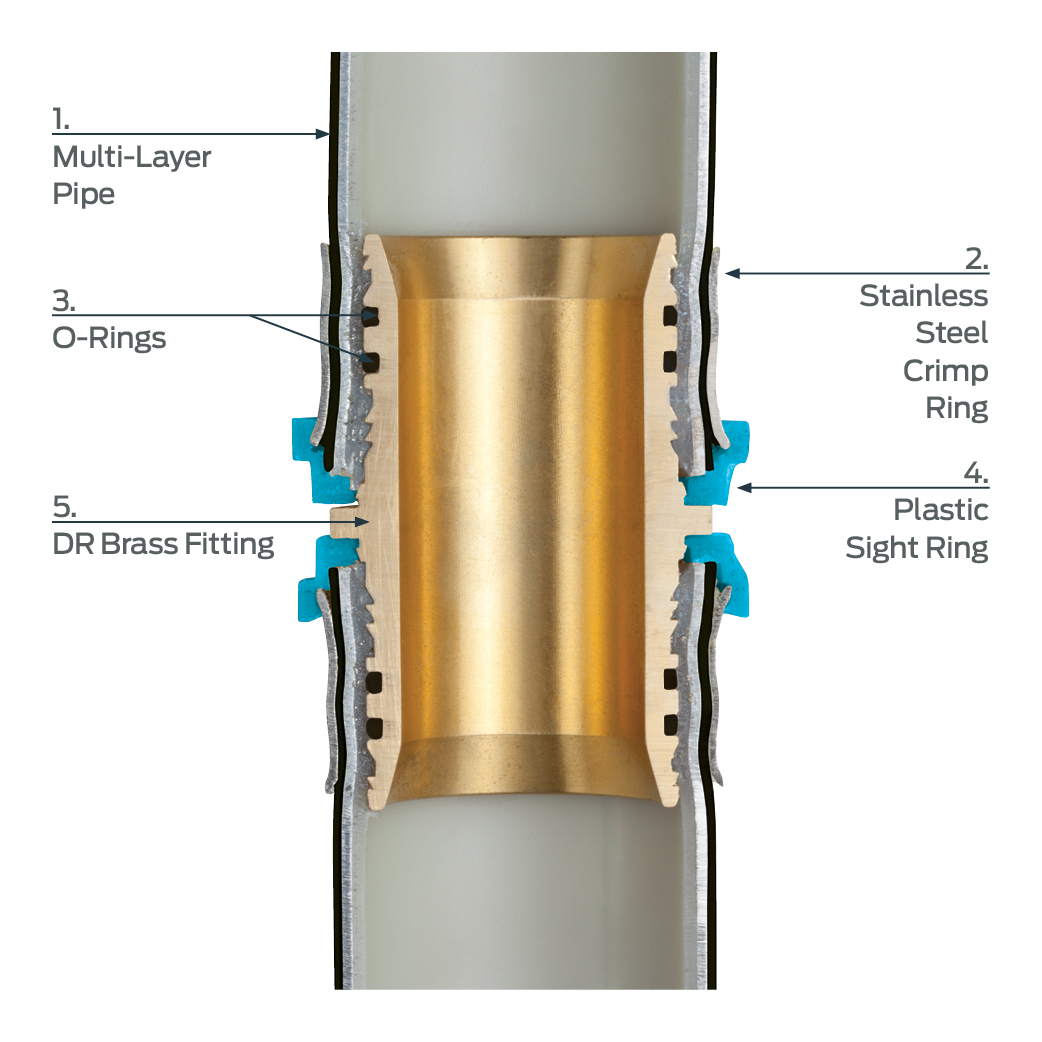

DuoPEX Water fittings are manufactured from dezincification resistance (DR) brass with a stainless steel crimp ring and joined to the pipe using a specific precision crimping tool.

To increase joint performance all DuoPEX Water crimp fittings are characterised by a plastic holding ring which has three important functions:

- As a locating ring that matches the DuoPEX Water jaws for a perfect crimp position

- It allows the installer to visually check when the pipe is correctly fitted on the fitting

- The fitting has a blue plastic holding ring to identify the fitting is for water installations only

The DuoPEX Gas fittings and DuoPEX Water fittings have different O-Ring compositions that are specific to their purpose.

The yellow holding ring indicates O-Rings for gas and the blue holding rings indicates O-Rings for water. Use the correct fitting for each application. This must be strictly adhered to.

Pipe and fittings are joined and sealed thanks to the stainless steel crimp ring mechanical deformation (2). This deformation is achieved by using the special DuoPEX Gas jaws.

- Multi-Layer Pipe

- Stainless Steel Crimp Ring

- O-Rings

- Plastic Sight Ring

- DR Brass Fitting

The Plastic Sight Ring aids in locating the jaws in the correct crimp position and features a witness hole to check the pipe has been fully inserted in the fitting.

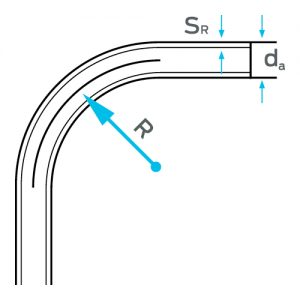

Bend Properties

Forming Stability

After bending, the DuoPEX Water pipe will remain stable, due to the aluminium layer. In many cases, thanks to this characteristic, it is possible to prefabricate assemblies before delivery to the site.

Minimum Bending Radii

Bending can be made manually, however if tighter bends are required, bending tools may be used.

The bending process on DuoPEX Water pipe must not result in either indentations or deformations on the inside of the pipe bend. Damage to the PEX layer of the DuoPEX Water pipe may effect the integrity of the system.

| Nominal diameter (da x s) |

Bending radius (R) without aid |

Bending radius (R) with bending spring |

Bending radius (R) with bending tool |

|---|---|---|---|

| 16 x 2.0 | 5 x da – 80 | 3 x da – 48 | 55 |

| 20 x 2.0 | 5 x da – 100 | 3 x da – 60 | 79 |

| 26 x 3.0 | 88 | ||

| 32 x 3.0 | 128 | ||

| 40 x 3.5 | 4.0 x da – 160 | ||

| 50 x 4.0 | 4.0 x da – 200 | ||

| 63 x 4.5 | 4.5 x da – 252 |

Note: All measurements in mm unless otherwise stated.

Thermal Properties

Thermal Changes in Length

Heating and cooling cause pipe length changes. The coefficient of expansion of DuoPEX Water composite pipes is 0.026 mm/m x k. For further information on Linear Expansion Tables and other expansion bend examples contact your DuoPEX representative.

| Example Temperature | |

|---|---|

| Differential ΔT | 50 k |

| Pipe length L | 5 m |

| Coefficient of expansion a | 0.026 mm/m.K |

| Linear expansion ΔL | 6.5 mm |

| ΔL | = a x L x ΔT = 0.026mm/m.K x 5 m x 50 K = 6.5 mm |

Thermal conductivity = 0.45 W/M x K

Fire and Excessive Heat

- Keep DuoPEX Water pipe a minimum of 500mm from sources of high heat, PEX such as heating appliances and flues from heating appliances

- Keep DuoPEX Water pipe 1500mm from slow combustion type stoves and flues used to heat hot water or cooking (wet back type)

- Leave 300mm minimum space between DuoPEX Water pipe and light fittings or other electrical fixtures

- DuoPEX Water pipe should not be positioned within 150mm of gas or central heating vents or flues

- Where fire collars or the like are required, installers should contact the manufacturer of those products to ensure they have certification for MLP construction

Uncontrolled Heat Sources

In the case of uncontrolled heat sources (e.g. slow combustion stoves, water heating coils, wet back boilers, solar, or similar) DuoPEX Water pipe should not be used. The primary flow and return on these types of heaters should not be installed in DuoPEX Water pipe. Secondary flow and returns must be controlled so that the temperature/pressure requirements are not exceeded.

In the interest of safe temperatures and to protect the user, tempering valves should be installed in accordance with AS/NZS 3500.

When using solar systems, installers should consult with manufacturers to ensure that water leaving the storage facilities does not exceed the performance capabilities of the pipe. Primary flow and returns should not be installed in DuoPEX Water pipe and secondary flow and returns must be controlled.

Temperature/Pressure Requirements

ISO 21003 allows PEX/AL/PEX pipes to be used at 1000kPa at a temperature of 70°C. For applications in excess of 1000kPa, please consult with your DuoPEX representative.

Fastening Spacing

| DN | Pipe Dimension | Maximum spacing of fasteners (S) | Pipe weight with water | |

|---|---|---|---|---|

| Horizontal | Vertical | (kg/m) | ||

| 12 | 16 x 2.0 | 1200 | 1500 | 0.225 |

| 15 | 20 x 2.0 | 1350 | 1500 | 0.355 |

| 20 | 26 x 3.0 | 1500 | 1750 | 0.608 |

| 25 | 32 x 3.0 | 1650 | 2000 | 0.935 |

| 32 | 40 x 3.5 | 2000 | 2000 | 1.438 |

| 40 | 50 x 4.0 | 2500 | 2500 | 2.264 |

| 54 | 63 x 4.5 | 2500 | 2500 | 3.611 |

Note: All measurements in mm unless otherwise stated.

UV and Chemical Resistance

Direct Sunlight Exposure

The outer layer of the DuoPEX Water pipe contains carbon black to the Australian Standard but should not be used in direct sunlight. Lay flat sleeving is available for sizes 32mm to 63mm, however this sleeving has a maximum UV life of 4 years and should be replaced prior to that time. Lay Flat sleeving is available in lilac and green for recycled and rainwater applications, but they do not offer any UV protection. It is best practice to sleeve exposed pipes.

16mm to 26mm pipe is not suitable for exposure to direct sunlight.

Temperature Correction Factor

| Temperature | Flow Velocity [V (m/s)] | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | |

| 10ºC | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 20ºC | 0.93 | 0.94 | 0.94 | 0.95 | 0.95 | 0.96 | 0.96 |

| 30ºC | 0.88 | 0.89 | 0.90 | 0.91 | 0.92 | 0.93 | 0.93 |

| 40ºC | 0.83 | 0.84 | 0.86 | 0.88 | 0.89 | 0.90 | 0.91 |

| 50ºC | 0.79 | 0.81 | 0.84 | 0.86 | 0.87 | 0.88 | 0.89 |

| 60ºC | 0.76 | 0.78 | 0.81 | 0.83 | 0.85 | 0.86 | 0.87 |

| 70ºC | 0.73 | 0.76 | 0.79 | 0.81 | 0.83 | 0.84 | 0.86 |

| 80ºC | 0.71 | 0.73 | 0.77 | 0.80 | 0.82 | 0.83 | 0.84 |

| 90ºC | 0.68 | 0.71 | 0.75 | 0.78 | 0.80 | 0.82 | 0.83 |

AS 4176

DuoPEX Water pipes and fittings have been certified in accordance with AS 4176.

Chemical Resistance

The chemical properties of polyethylene are significantly improved by the cross-linking process.

DuoPEX Water pipes are resistant to the following media:

-

Concrete, plaster, mortar, and cement

-

Disinfectants and cleaning agents according to DVGW worksheet W 291 and DIN 2000

-

All natural potable water constituents

-

Corrosion – protection agents according to DIN 1988 Part 4

DuoPEX Water pipes must be protected against:

- Direct contact with bitumen or bitumen strips

- Greases, solvents and oils

- Contaminated areas as defined in AS/NZS 3500

If the DuoPEX Water system is used in areas where, for example, aggressive gases, permanently acting moistures or building materials containing chlorine are to be encountered, the pipe and fittings must be protected using suitable jacketing.

It is also best practice to protect fittings with suitable jacketing when in contact with screed, concrete, mortar or plaster. Always consult the manufacturer for details.

Burial

The DuoPEX Water system can be used below ground in accordance with AS/NZS 3500 Part 1 and Part 4.

It is also best practice to protect pipe and fittings with suitable jacketing when buried in contaminated soil.