Auspex Gas

Properties

The Auspex Gas pipe and fitting system is a revolutionary alternative for the professional plumber and gasfitter that makes any job quicker and easier.

Only available in Australia.

Auspex Gas Fittings

The Auspex Gas system has been specifically designed to be compatible with the one universal fitting for both water and gas.

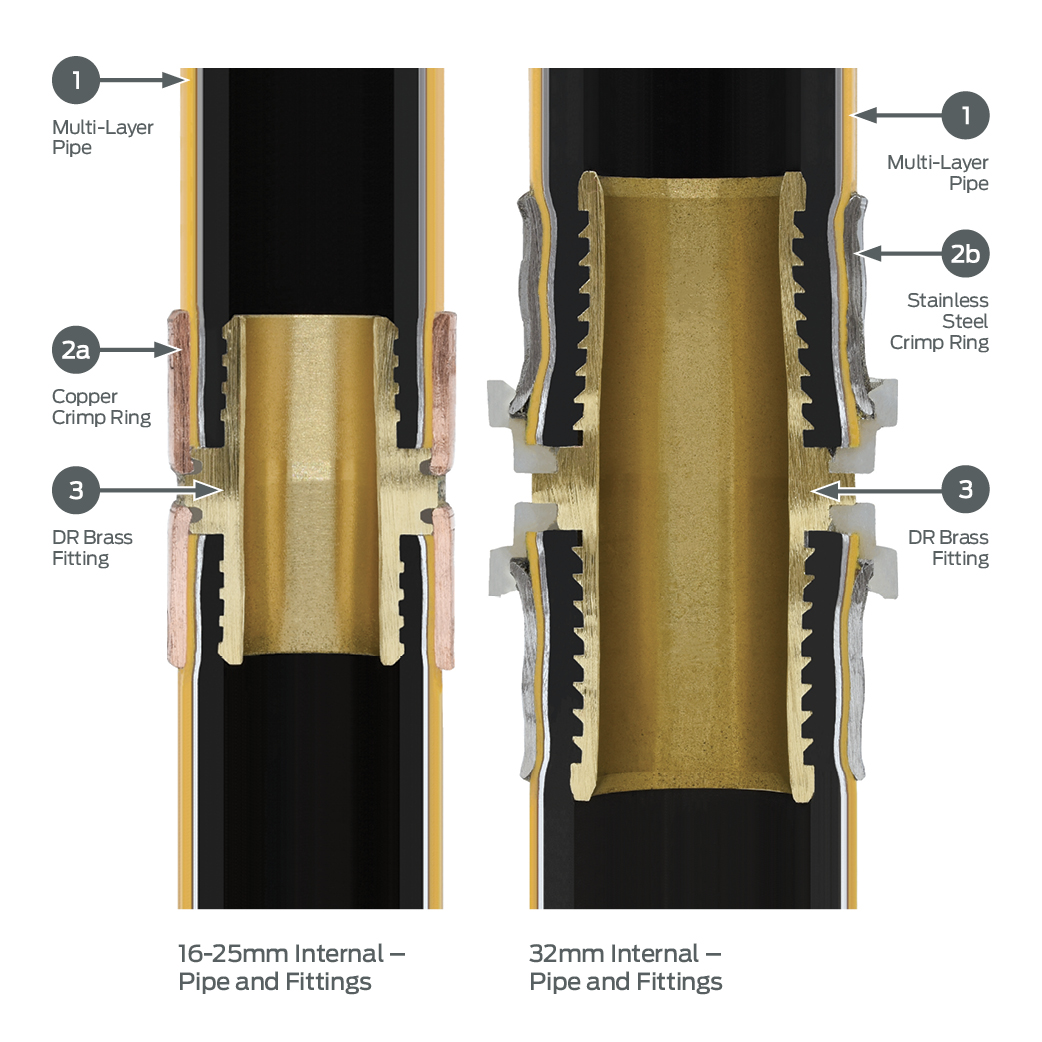

The Auspex Gas range of fittings are manufactured from dezincification resistance (DR) brass. The 16, 20, 25mm fittings have a copper ring and use the Auspex Crimp tool. The 32mm fittings are stainless steel crimp with a plastic ring and use the DuoPEX crimp tool.

Reliable joint performance is maintained with witness holes. Witness holes are provided on the copper and stainless steel crimp rings to visually verify full insertion of the pipe into the fitting. Auspex hand crimping tools can be used up to 25mm, with the Rothenberger battery tool capable of all sizes.

The system is designed to use the same battery tools and jaws that are used on the Auspex water system 16mm to 32mm. The Auspex hand tools can be used on sizes 16mm to 25mm with a checking gauge to ensure correct tool adjust, DuoPEX jaws are required in the Auspex 32mm white ring fittings.

The system has been tested and certified using the Auspex and DuoPEX tools available exclusively from Reece. Tools other than these will not be warranted.

Auspex water fittings are available for Auspex Gas pipe in sizes 16mm to 32mm.

Auspex Gas crimp fittings are classified as a permanent joint in accordance with AS/NZS 5601. As such, the fittings should not be able to move inside the pipe after crimping has been done.

Pipe and fittings are joined and sealed by the deformation caused by correct crimping of the copper crimp ring in sizes 16mm to 25mm and similarly with the stainless steel crimp ring in 32mm.

Auspex Gas Pipe

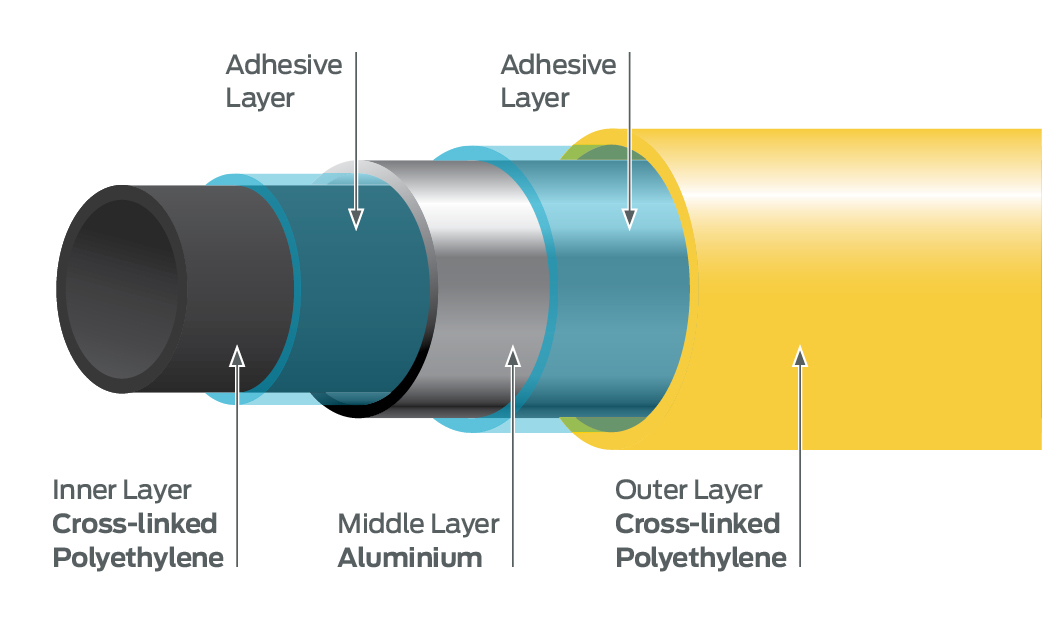

The Auspex Gas System is a multi-layer pipe made from Cross Linked Polyethylene (PEX) on both layers and aluminium in between. Having PEX on both layers ensures that the highest performing polymer is on both sides of the aluminium core. Auspex Gas has a defining black inner layer and can easily be identifed.

Do not use pipes that have kinks, cuts, deep scratches, squashed ends, imperfections or have been in contact with contaminating substances. Such pipe should be cut out and replaced, as these conditions may affect the integrity of the system.

The wall thickness of the multi-layer pipes have been specifically engineered to match the SDR 9 Auspex single layer water pipes. This allows most Auspex water fittings to be compatible with the Auspex Gas pipes. Auspex water fittings have copper crimp rings in sizes 16mm, 20mm and 25mm. Stainless steel crimp rings are used on 32mm fittings.

Auspex Gas pipe has been tested and certified in accordance with AS 4176.

Data Sheet

| Dimension (mm) | 16 | 20 | 25 | 32 |

|---|---|---|---|---|

| Coefficient of Linear Thermal Expansion in mm/m x K | 0.026 | 0.026 | 0.026 | 0.026 |

| Thermal Conductivity in W/M x K | 0.45 | 0.45 | 0.45 | 0.45 |

| Gas Volumes Litre/m | 0.1112 | 0.1814 | 0.2955 | 0.4752 |

| Pipe Roughness K mm | 0.007 | 0.007 | 0.007 | 0.007 |

| Coil Length | 50 | 50 | 50 | 25 |

| Metres Per Length | 5 | 5 | 5 | 5 |

| Pipe Weight (G/M) | 109 | 159 | 229 | 389 |

Bend Properties

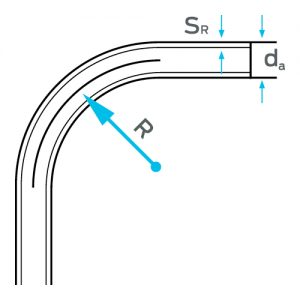

Bending of Auspex Gas Pipe

Auspex Gas pipe is supported by the aluminium layer and will remain stable after bending. Bending can be done manually, however, bending tools are available if required. Care must be taken during this process to ensure that the pipe does not kink or deform, as these may affect the performance of the system.

The bending process on Auspex Gas pipe must not result in either indentations or deformations on the inside of the pipe bend. Damage to the PEX layer of the Auspex Gas pipe may effect the integrity of the system.

Do not use pipes that have kinks, cuts, deep scratches, squashed ends, imperfections or have been in contact with contaminating substances. Such pipe should be cut out and replaced, as these conditions may affect the integrity of the system.

| Nominal diameter (da x s) |

Bending radius (R) without aid |

Bending radius (R) with bending spring |

Bending radius (R) with bending tool |

|---|---|---|---|

| 16 | 5 x da | 2.0 x da | |

| 20 | 5 x da | 3.0 x da | |

| 25 | 3.6 x da | ||

| 32 | 3.6 x da |

Note: All measurements in mm unless otherwise stated.

Thermal Properties

Thermal Changes in Length

Heating and cooling cause pipe length changes.

The coefficient of expansion of Auspex Gas composite pipes is 0.026 mm/m x k.

For further information on Linear Expansion Tables and other expansion bend examples contact your Auspex representative or customer service.

| Example Temperature | |

|---|---|

| Differential ΔT | 50 k |

| Pipe length L | 5 m |

| Coefficient of expansion a | 0.026 mm/m.K |

| Linear expansion ΔL | 6.5 mm |

| ΔL | = a x L x ΔT = 0.026mm/m.K x 5 m x 50 K = 6.5 mm |

Thermal conductivity = 0.45 W/M x K

Fire and Excessive Heat

-

Keep Auspex Gas pipe a minimum of 500mm from sources of high heat, such as heating appliances and flues from heating appliances. If any hot joints are made in the line such as welding, the joints involved must be disconnected from the pipe and cooled completely before rejoining to the pipe

-

Keep Auspex Gas pipe 1500mm from slow combustion type stoves and flues used to heat hot water or cooking (wet back type)

-

Leave 300mm minimum space between Auspex Gas pipe and light fittings or other electrical fixtures

-

Auspex Gas pipe should not be positioned within 150mm of gas or central heating vents or flues

-

Where fire collars or the like are required, installers should contact the manufacturer of those products to ensure they have certification for MLP construction

Spacing of Supporting Devices

| Pipe Dimension | Max Pipe clip clearance |

|---|---|

| 16 | 1000 |

| 20 | 1250 |

| 25 | 1500 |

| 32 | 2000 |

Note: All measurements in mm unless otherwise stated.

See also AS/NZS 5601. Synthetic clips must be used.

UV and Chemical Resistance

UV Resistance

Auspex Gas pipes must be protected against direct sunlight or UV radiation. Consequently, Auspex Gas pipes must be covered during transport or storage if they have been removed from their original packaging. When Auspex Gas pipes are used in a UV stabilised sleeve, adequate UV protection is assured during the installation phase. Furthermore, jackets made from insulating material can undertake the function of UV protection with Auspex Gas pipes (check with the supplier of the insulating material).

It is best practice to ensure that piping is installed out of direct sunlight.

Chemical Resistance

Auspex Gas has been tested and certified to AS 4176.8. This standard covers multi-layer pipe and fittings in domestic gas installations for natural gas and LPG.

Gas pipes must be protected from exposure to

-

Bitumen or bitumen strips

-

Greases, solvents, and oils

-

Contaminated areas as defined by AS/NZS 5601 and AS/NZS 3500

Auspex Silicone Burial Wrap

Make an Auspex connection ensuring pipe is inserted to proper depth. While leaving the protective film in place, measure the amount of tape needed to completely wrap the fitting. To ensure a proper seal, overlap tape by 25mm past the end of the fitting on every end and 6-12mm between/across the fitting.

Wrap the fitting by pulling the tape tight and removing the protective film. Completely cover the fitting. The tape will bond to itself within minutes and will cement to itself within a few hours forming an air and water tight seal.

Sleeving & Protection

If the Auspex Gas system is used in areas where, for example, aggressive gases, below ground, permanently acting moistures or building materials containing chlorine are to be encountered, the fittings must be protected using RWC silicon wrap.

It is also best practice to protect pipe and fittings with suitable jacketing when similarly exposed or in contact with screed, concrete, mortar, plaster or similar.